This article provides an overview of the various parts of a gate valve, highlighting their functions and importance in valve operation. From the body and bonnet to the gate and stem, explore how each element contributes to the efficient flow control provided by gate valves. Gain a comprehensive understanding of the key components, their roles, and the applications where gate valves excel.

The Parts of a Gate Valve

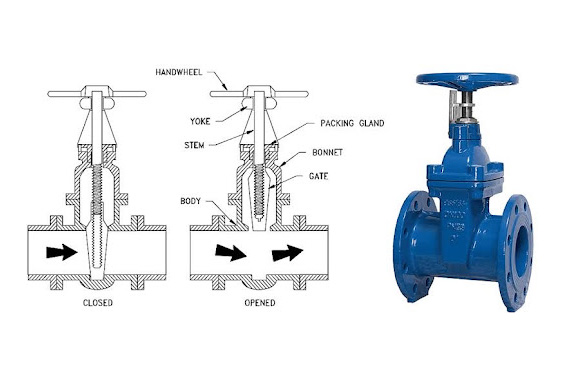

Gate valves are vital for flow control in various industries, and understanding their components is essential. This article provides an overview of the different parts that make up a gate valve, explaining their functions and significance. By exploring the body, bonnet, gate, seat assembly, stem, and packing of a gate valve, you will gain valuable insights into how these components work together to ensure efficient flow control. Familiarize yourself with the anatomy of a valve to appreciate its reliability and effectiveness in numerous applications.

The Body and Bonnet of a Gate Valve

The body and bonnet form the main housing of a gate valve. The body provides the primary structure that contains the internal components and directs the flow of fluid. It features inlet and outlet ports, allowing the medium to enter and exit the valve. The bonnet, on the other hand, encloses the stem and packing, providing a seal to prevent leakage.

The Gate and Seat Assembly

The gate and seat assembly is one of the critical components responsible for regulating the flow of fluid. The gate is a wedge-shaped element that moves up and down within the valve body. When the gate is fully raised, it allows unrestricted flow, and when lowered, it creates a tight seal, preventing the passage of fluid. The seat, located on the body, provides a sealing surface against which the gate rests when closed. It ensures a watertight closure, preventing leakage when the valve is in the closed position. The gate and seat assembly is typically made of materials such as stainless steel or brass, which offer excellent sealing and corrosion resistance properties.

The Stem and Packing

The stem connects the gate to the actuator or handle of the valve, allowing for manual or automated operation. It transmits the movement from the actuator to the gate, enabling precise control of the valve opening or closing. The stem is usually made of stainless steel or carbon steel to withstand mechanical forces and maintain structural integrity. To prevent leakage along the stem, packing material, such as PTFE or graphite, is used. The packing surrounds the stem and provides a tight seal, ensuring that no fluid escapes from the valve body during operation.

Conclusion: Understanding the Importance of Gate Valve Components

The components of a gate valve work together to facilitate efficient flow control in various applications. From the body and bonnet that house the internal mechanisms to the gate and seat assembly that regulate fluid flow, each component plays a vital role. The stem and packing ensure smooth operation and prevent leakage. By comprehending the functions and significance of each part, you can appreciate the reliability and effectiveness of gate valves. Whether in water treatment plants, oil and gas refineries, or industrial processes, gate valves perform essential flow control tasks, thanks to their well-designed components.