Explore the seamless synergy of strength and adaptability with stainless steel grooved flexible couplings. This article delves into the diverse applications and advantages of these couplings, from enhancing pipeline integrity to simplifying installation processes. Discover how stainless steel grooved flexible couplings revolutionize connections in various industries.

Introduction:

Embark on a journey of precision and adaptability with Stainless Steel Grooved Flexible Couplings. This article unravels the applications and benefits of these couplings, shedding light on their pivotal role in ensuring seamless connections across diverse industries.

Unveiling Stainless Steel Grooved Flexible Couplings

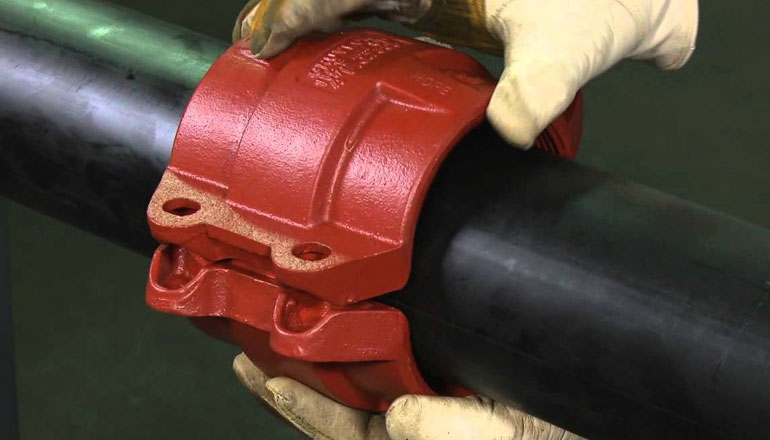

Stainless Steel Grooved Flexible Couplings redefine connection standards with their robust design and flexible grooved structure. These couplings serve as a linchpin in various systems, providing a reliable link that accommodates movement while maintaining structural integrity.

Pipeline Integrity Reinforced

In the realm of fluid and gas pipelines, these grooved flexible couplings play a vital role in reinforcing integrity. Their ability to absorb vibrations and movements ensures that pipelines remain secure and leak-free even in dynamic environments. This feature makes them indispensable in industries where pipeline stability is paramount, such as oil and gas.

Simplifying Installation Processes

One of the standout features of these couplings is their ease of installation. The grooved design allows for quick and straightforward connections, reducing installation time and costs. This simplicity in installation makes these couplings an attractive solution for projects where efficiency is a priority, such as construction and firefighting systems.

Adaptability to Temperature Fluctuations

Stainless steel’s inherent resistance to temperature extremes makes grooved flexible couplings versatile in diverse climates. From freezing temperatures to scorching heat, these couplings maintain their structural integrity, ensuring reliable connections regardless of environmental conditions. Industries with operations in challenging climates, such as manufacturing and petrochemicals, benefit from this adaptability.

Corrosion Resistance for Longevity

The stainless steel composition of these couplings provides a natural defense against corrosion. This resistance significantly extends the lifespan of the couplings, reducing maintenance costs and enhancing the overall reliability of connected systems. Real-world examples abound in marine and coastal applications, where exposure to saltwater demands corrosion-resistant solutions.

Applications Across Industries

These flexible couplings find applications across a spectrum of industries, from HVAC systems in commercial buildings to water treatment plants. Their versatility in accommodating movement and absorbing shocks ensures uninterrupted operations, making them a preferred choice where precision and reliability are non-negotiable.

Conclusion:</h2>

In conclusion, Stainless Steel Groove

d Flexible Couplings emerge as a cornerstone in ensuring precise and adaptable connections. From reinforcing pipeline integrity to simplifying installation processes.

These couplings showcase their versatility across industries. Upgrade your connections, and enhance efficiency—experience the transformative impact of Stainless Steel Grooved Flexible Couplings in diverse applications.