In this comprehensive article, we will delve into the innovative world of flow control and explore the engineering marvel known as the Triple Offset Butterfly Valve. With a unique design that guarantees leak-tight performance and precise throttling, this valve has revolutionized various industries. From oil and gas to chemical processing, understanding the principles behind this engineering marvel can unlock a world of possibilities for efficient fluid handling.

What is a Triple Offset Butterfly Valve?

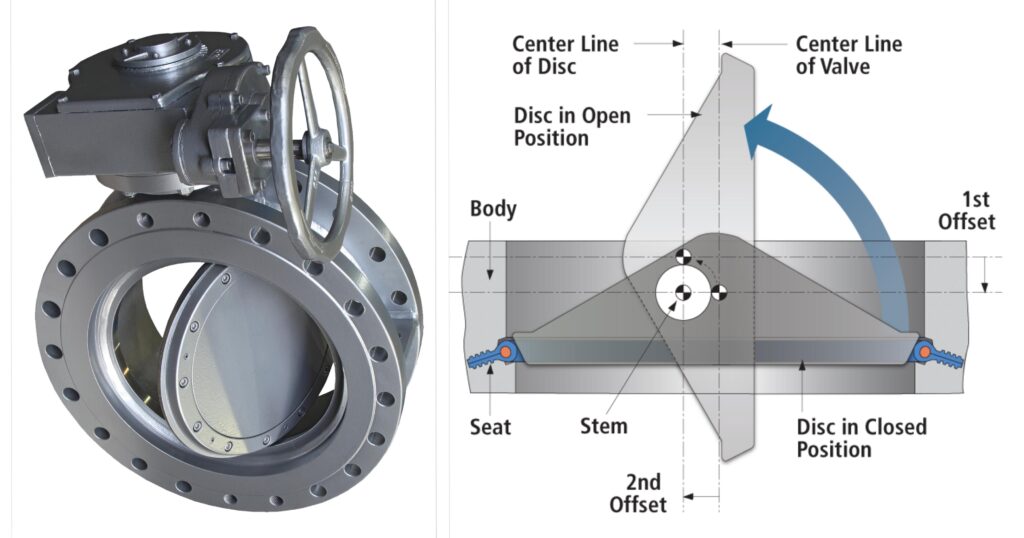

The Triple Offset Butterfly Valve is a cutting-edge flow control device used to regulate the flow of liquids and gases in pipelines. Its unique triple offset design ensures a bubble-tight seal with no leakage, making it ideal for critical applications where safety and reliability are paramount.

How Does It Work?

This valve’s operation is based on three offsets: the shaft offset, the cone axis, and the sealing surface. As the valve disc rotates, it achieves a tight, frictionless seal against the seat. This precise control eliminates the need for gaskets and minimizes wear and tear, extending the valve’s service life.

Applications in Diverse Industries

The Valve finds extensive use in various industries. For instance, it plays a vital role in oil and gas production, facilitating the transportation of crude oil and natural gas with unmatched efficiency and safety. Moreover, it is an essential component in chemical processing plants, where precise flow control is critical to ensure product quality.

Advantages Of Traditional Valves

Compared to traditional valves, the Triple Offset Butterfly Valve offers several key advantages. Its frictionless design reduces wear, minimizing maintenance and downtime. Furthermore, its bubble-tight seal guarantees zero leakage, promoting safety and preventing environmental hazards.

Real-life Example:

Triple Offset Valve in Offshore Platforms An excellent example of the Butterfly Valve’s prowess is its usage in offshore oil platforms. These platforms face harsh conditions, and any valve failure can lead to catastrophic consequences. By employing triple offset technology, these valves provide reliable and robust performance, ensuring uninterrupted oil extraction even in challenging environments.

Factors to Consider for Proper Selection

When selecting a Triple Offset Butterfly Valve for specific applications, certain factors come into play. Understanding the fluid characteristics, pressure, temperature, and compatibility with the medium are crucial to ensure optimal valve performance.

Maintaining and Extending

Valve Lifespan Proper maintenance is essential to maximize the valve’s lifespan and performance. Regular inspections, lubrication, and addressing potential issues proactively can significantly extend the valve’s service life, reducing operational costs in the long run.

Conclusion

The Butterfly Valve represents a breakthrough in flow control technology, surpassing traditional valves in efficiency, safety, and reliability. Its application in various industries showcases its adaptability and unmatched performance. By understanding its inner workings and proper selection, engineers, and operators can harness its full potential, ensuring seamless and safe fluid handling in critical processes.

With the Triple Offset Butterfly Valve at the forefront of modern flow control, industries can embrace a new era of efficiency and precision, propelling them toward success in an ever-evolving world.