This comprehensive article explores the features, benefits, and applications of Lug butterfly valves. Learn how these valves function, their advantages over other types, and why they are essential in various industries. Whether you’re a professional or a curious reader.

Lug butterfly valves are indispensable components in fluid management systems. With their exceptional performance and versatility, these valves enable efficient flow control across a wide range of applications. This article delves into the features, benefits, and applications of these valves, shedding light on their significance in modern industries.

What Is a Lug Butterfly Valve and How Does It Work?

Lug butterfly valves are quarter-turn valves that regulate fluid flow by using a disc mounted on a rotating shaft. This disc, positioned in the center of the pipe, controls the flow by rotating parallel or perpendicular to the pipe axis.

Advantages

Lug butterfly valves offer numerous advantages over other valve types, making them a preferred choice in various industries. These advantages include:

- Versatility: These valves can handle a wide range of fluids, including liquids, gases, and slurries, making them suitable for diverse applications.

- Cost-Effective: With lower installation and maintenance costs compared to gate or ball valves, butterfly valves provide a cost-effective solution without compromising performance.

- Efficient Flow Control: The quarter-turn operation of butterfly valves allows for quick and precise flow adjustment, ensuring optimal process efficiency.

- Compact Design: These valves have a compact and lightweight design, resulting in space savings and ease of installation, especially in tight spaces.

Applications of Lug Butterfly Valves

Lug butterfly valves find applications in various industries, including:

- HVAC Systems: These valves are used in heating, ventilation, and air conditioning systems, ensuring efficient fluid regulation and control.

- Water Treatment: These valves play a crucial role in water treatment plants, facilitating the control and isolation of water flow during filtration, purification, and distribution processes.

- Chemical Processing: These products are widely utilized in chemical plants for handling corrosive chemicals, acids, and aggressive fluids, thanks to their durability and chemical resistance.

- Food and Beverage Industry: Lug butterfly valves meet the stringent sanitary requirements of the food and beverage industry, providing hygienic fluid control in processing and packaging operations.

Choosing the Right Lug Butterfly Valve

When selecting a Lug butterfly valve, consider the following factors:

- Pressure and Temperature Ratings: Ensure the valve is suitable for the operating pressure and temperature conditions of your application.

- Material Selection: Select a valve made from materials compatible with the fluid being handled, considering factors such as corrosion resistance and hygiene requirements.

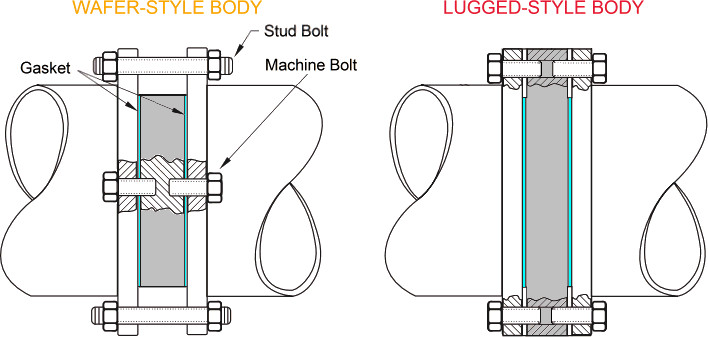

- End Connection: Choose the appropriate end connection type, such as wafer or lug, based on your installation requirements.

Conclusion

In conclusion, Lug butterfly valves are reliable and versatile components that offer efficient flow control in various industries. Their cost-effectiveness, compact design, and ease of operation make them an ideal choice for fluid management applications. By understanding the features, advantages, and applications of valves, professionals and enthusiasts can make informed decisions when it comes to fluid control systems.

Remember, whether you’re overseeing an HVAC project, managing water treatment processes, or involved in chemical processing or the food and beverage industry, these products can provide the performance and reliability you need. Invest in Lug butterfly valves for seamless flow control and enhanced operational efficiency.