Discover the versatility and efficiency of slide gate valves for precise flow control in various industries. A slide gate valve is a crucial component used to regulate the flow of bulk materials in systems handling solids, powders, and granules. This article explores the functionality, advantages, and applications of slide gate valves. From material handling in manufacturing plants to grain storage and processing facilities, incorporating a slide gate valve into your system ensures reliable and efficient flow control, optimizing productivity and minimizing downtime.

Slide Gate Valve: Unlocking Efficient Flow Control

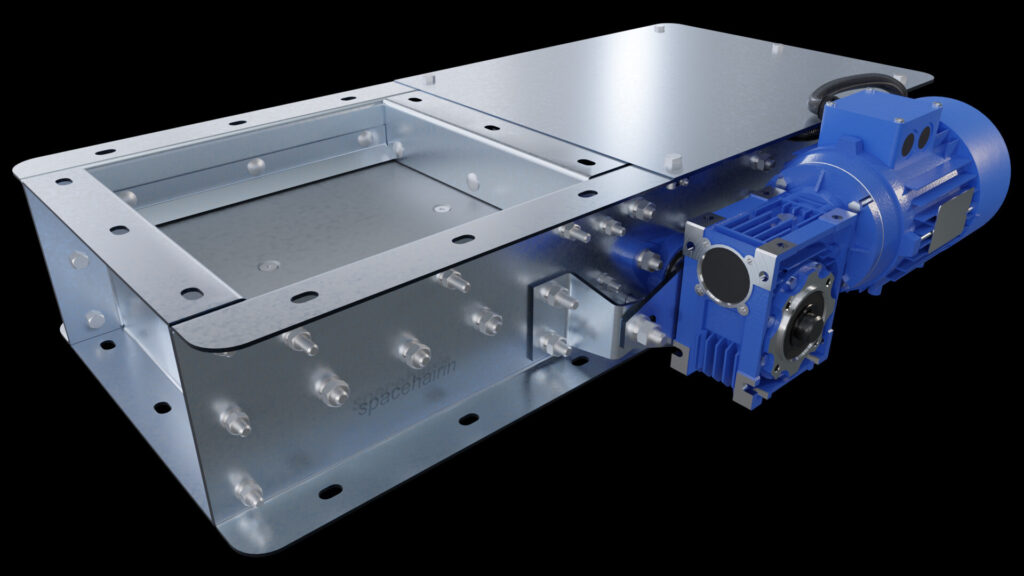

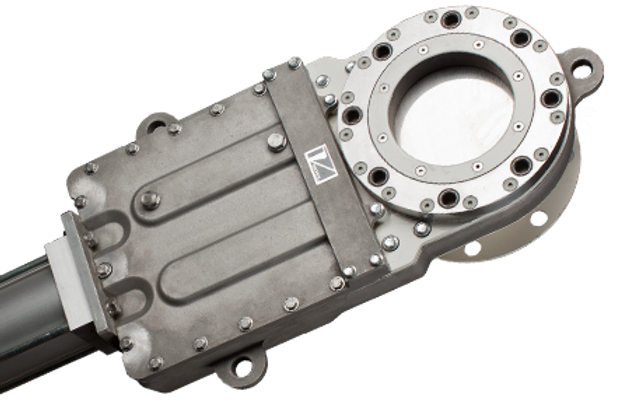

A slide gate valve is a versatile equipment designed to regulate the flow of bulk materials with precision. With its unique sliding mechanism, this valve offers numerous benefits and finds applications in various industries, revolutionizing flow control processes.

How Does a Slide Gate Valve Work?

A slide gate valve operates by using a sliding plate or gate to control the flow of materials. This sliding action provides a reliable and efficient means of flow control, ensuring seamless material handling operations.

Advantages of Using

- Precise Flow Control:

Slide gate valves offer precise control over the flow of bulk materials, allowing operators to regulate the rate and volume of material discharge accurately. This ensures optimal process performance and minimizes wastage or spillage. - Versatility:

Slide gate valves are highly versatile and can handle a wide range of bulk materials, including powders, granules, and abrasive substances. They are suitable for diverse industries such as mining, food processing, chemicals, and agriculture. - Minimal Maintenance:

With their simple design and fewer moving parts, slide gate valves require minimal maintenance. This reduces downtime and associated costs, contributing to overall operational efficiency. - Compact Design:

Slide gate valves are compact in size, making them ideal for installations where space is limited. Their small footprint allows for flexible integration into existing systems without significant modifications.

Applications of Slide Gate Valves

- Material Handling in Manufacturing:

Slide gate valves are commonly used in manufacturing plants for the controlled transfer of bulk materials between different process stages. They ensure precise material flow in conveying systems, hoppers, and silos, optimizing production efficiency. - Grain Storage and Processing:

In the agricultural industry, slide gate valves play a vital role in grain storage facilities and processing plants. They enable the controlled discharge of grains from silos, ensuring efficient inventory management and preventing material degradation. - Chemical and Pharmaceutical Industries:

Slide gate valves find applications in the chemical and pharmaceutical sectors, where accurate dosing, blending, and batching of powdered or granular materials are critical. These valves facilitate precise material flow control in various processes, enhancing product quality and consistency.

Conclusion

In conclusion, a slide gate valve is an essential component for efficient flow control in industries handling bulk materials. Its precise control, versatility, minimal maintenance, and compact design make it a valuable asset in material handling, grain storage, and chemical processing applications. By incorporating a slide gate valve into your system, you can optimize flow control, minimize wastage, and enhance overall operational efficiency. Embrace the benefits of a slide gate valve and unlock reliable and efficient material flow control in your processes.