This article highlights the significance of exhaust butterfly valves in optimizing engine performance. As a crucial component in the exhaust system. The exhaust butterfly valve regulates exhaust gas flow, improving engine efficiency, power delivery, and emissions control. The article explores the working principle, benefits, and applications of exhaust butterfly valves in automotive and industrial settings. By understanding the importance of these valves. Manufacturers and engine enthusiasts can make informed decisions to enhance engine performance.

Introduction to Exhaust Butterfly Valves

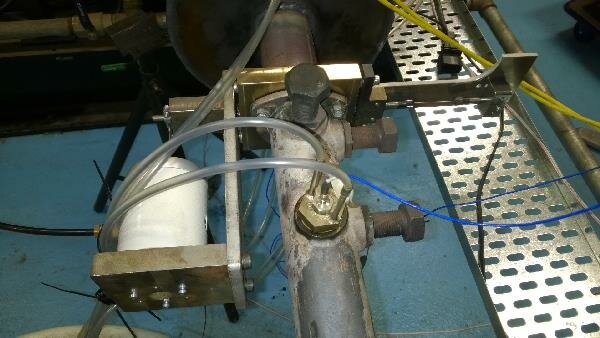

The exhaust butterfly valve is a device in the exhaust system of an engine to control the flow of exhaust gases. It consists of a disc or plate, known as the butterfly, which pivots within the exhaust pipe. By adjusting the position of the butterfly, the valve can either restrict or allow the passage of exhaust gases, optimizing engine performance based on specific conditions.

Benefits and Applications of Exhaust Butterfly Valves

- Engine Performance Optimization: The exhaust butterfly valve enables precise control over exhaust gas flow. Facilitating improves power delivery and torque. By adjusting the valve’s position, engine performance characteristics can tailor to different driving conditions, enhancing overall efficiency and responsiveness.

- Emissions Control: Exhaust butterfly valves play a crucial role in emissions control by regulating the flow of gases through the exhaust system. They aid in achieving compliance with emissions regulations. Reducing harmful pollutants, and promoting environmental sustainability.

- Sound Management: In automotive applications, exhaust butterfly valves utilize to control exhaust sound levels. By adjusting the valve’s position, the exhaust note can modify to deliver a desired sound profile. Enhancing the driving experience without compromising performance or legal requirements.

- Turbocharger Response Optimization: In turbocharged engines, exhaust butterfly valves often incorporates in the exhaust manifold or turbine housing. By manipulating the valve position. The back pressure on the turbocharger can regulate, optimizing spool-up time and improving overall turbocharger response.

Future Trends and Innovations in Exhaust Butterfly Valve Technology

The future of exhaust butterfly valves marks by continuous innovation and advancements in technology. Manufacturers are focusing on developing intelligent valve systems that can dynamically adjust based on real-time engine parameters. These systems may utilize electronic control units (ECUs) and sensors to optimize exhaust gas flow and maximize engine performance across a wide range of operating conditions.

Furthermore, there is a growing emphasis on lightweight materials, such as titanium and carbon fiber, to enhance valve responsiveness and reduce overall weight. Integration with advanced engine management systems and the use of computational fluid dynamics (CFD) simulations are also driving advancements in valve design and optimization.

Conclusion:

Exhaust butterfly valves play a crucial role in optimizing engine performance, emissions control, and sound management. Their ability to regulate exhaust gas flow allows for enhanced power delivery, improving turbocharger response, and compliance with environmental regulations. With ongoing advancements in technology and a focus on innovation, the future of exhaust butterfly valves holds promise for further improving engine performance and efficiency. By leveraging the benefits of these valves, manufacturers and engine enthusiasts can unlock the full potential of their engines.