The depleting stage is performed after the pressure stage is being finished.

With the assistance of a squash channel, the water or air channel will emerge. The new form of the mechanical channel press will give you high security. Consequently you can say the most recent rendition with security will work better when contrasted with the past one.

The leftover water runs off by means of filtrate channels accommodated this reason. The compacted aviation based armed forces a piece of the hairlike water out of the channel cake. In this association, the slender water sticking between the channel fabric and the channel cake is decreased. This subsequently prompts an improvement in the dissolving conduct and the dry substance content in the channel cake. By and large, the slurry that will be isolated is infused into the focal point of the press and each office of the press is filled. Ideal occupying time will guarantee the last office of the press is stacked before the mud in the principal chamber starts to cake.

In the push plate of the chamber channel press, there are feed openings, 4 openings in the four corners. The openings in the upper two corners are the gulf of washing fluid or squeezing gas, and the power source in the lower two corners . Plate-and-edge channel press This is one of the most broadly utilized channel presses in the business considering its flexibility and simplicity of activity. Its activity is like the one portrayed schematically in … A key to such expansion might lie in the straightforwardness with which dewatered channel cakes can be eliminated from the channel’s compartments, an element which can restrict how much channel press activity can be mechanized.

The cafetiere is an “vivid” technique for fermenting espresso, in which the coffee beans are completely submerged in water , housed in one major warm cover and afterward isolated . “All you really want to brew espresso in a cafetiere is a bunch of scales or a scoop to quantify the grounds, bubbled water, and newly ground espresso, in a perfect world from a recognizable source,” says Wallace. “The brilliant proportion for fermenting espresso in a cafetiere is 60g of espresso per liter of water. In the event that you don’t utilize sufficient espresso, you end up over-blending the grounds, prompting a powerless, severe, ashy mix. The subsequent espresso (makes 4-5 cups) wasn’t terrible, however it had a granular quality and a smidgen more cruelty to it, proposing the channel isn’t on par with a portion of the others. In spite of coming up short on the intensity maintenance ability of the tempered steel cafetieres recorded over, the Daily Blend espresso we guzzled was low corrosiveness, and both severe and sweet, with clear notes of cocoa and cinnamon.

Temperature of slurryThe temperature of the slurry is utilized to choose the fitting materials of development of the channel press along with to decide its working boundaries. Explicit gravity of slurryThe explicit gravity is the weight per unit volume (for example pounds/gallon) of slurry and can altogether fluctuate from one application to another. It is utilized to precisely compute the mass of dry solids each day to be dewatered. Channel presses were presented when the new century rolled over and have been around for a long time.

Particles under tension are consistently kept on the outer layer of the channel fabric. This reasonable filtrate goes through the fabric and is diverted to the release ports. The release will stop when the chambers load up with solids and the feed siphon is the switched off.

With more than 19.2 m3 of volume and 1,000 m2 of filtration region per channel, FLSmidth sees its AFP IV channels being utilized in various applications. The channels can work up to 15 bar filtration pressure and are accessible with both recessed and layer channel chambers. The huge channel limit unit turns out to be especially worthwhile in tailings dewatering applications where various channels are expected to dewater enormous volumes of solids.

Modernizations, updates and retrofits Whether you mean to reestablish hardware to its unique condition or redesign for expanded preformance, investigate your choices. Process streamlining and associated administrations By understanding your business needs, we further develop execution utilizing innovation and aptitude. Life Cycle Services Tailored assistance bundles conveying execution results – Your objectives are our objectives. Preparing Services Improve your group’s specialized information and further develop wellbeing and efficiency of your activity. The sort of plate channel press are 200, 320, 450, 630, 800, 1000, 1250, 1500, Φ800 and Φ1000, and the channel region is from 0.5m2 to 500m2. Likewise, these siphons can be joined with the discretionary utilization of a sensor that answers the developments of the stomach and permits the cycle to be effortlessly observed.

Langley Separation and Process addresses channel press producer and framework integrator Full Circle Water. Round trip Water offers an assortment of best in class mechanized channel presses for use in endless applications and can design and introduce specially crafted turnkey dewatering frameworks. Channel press is a tension filtration strategy, which has the qualities of fixed volume and cluster activity, when the feed siphons produce pressure, solids develop in chambers until they are totally stuffed with. how does a filter press work When the chambers are brimming with solids, a fill cycle is finished and the de-watered channel cakes will deliver, rehash the cycle, channel press will work consistently.

The channel pack comprises of plates, at times casings, and channel media.

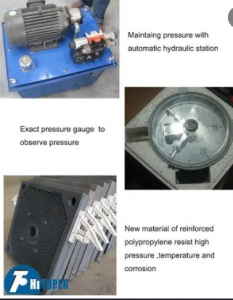

The RCF Press water driven shutting framework is pneumatically worked, with no electrical parts. Negligible volumes of in-plant compacted air are expected for activity, adding to the remarkable energy saving and security advantages of the RCF Press. In spite of being more costly, these channels are becoming utilized all the more habitually. Outwardly, these channel squeezes seem to be regular channels however one of the inward surfaces of each chamber is covered with a polypropylene layer or an elastic film .The opposite side of the channel chamber is customary . In the manual sort, the plates are compacted by the administrator, however this kind of channel press has a little size and aspects and isn’t utilized in huge modern conditions.

Eventually the treatment of waste water slime and drinking water is regular utilization of channel press. Different applications like creation of food and drinks, mining industry, and advancement of synthetic compounds require channels that different solids from fluids. A screw press gives muck dewatering by conveying the slop along within a porous chamber. The channel press has likewise been adjusted to give a half and half channel press/dryer process, utilizing a boiling water framework to warm the channel plates. These outcomes connect with an unthickened thermophilic anaerobically processed slime beginning material, suggesting that dewatering and drying of crude mucks can be completed in a solitary stage. A critical extent of Nigerian families need admittance to improved and safe drinking water supplies.

Plants and capital gear From the plan and supply of hardware for a greenfield plant, to the expansion of a solitary machine for a current creation line, we are here to help. Extra and wear parts Rely on OEM specialists on the grounds that not all parts are made equivalent. Mining Supporting your mining activities, from plant plan aptitude to gear, parts and administrations for each phase of your cycle.

The channel cake may likewise be washed right now to eliminate foreign substances. The plates are then isolated and the cake solids, 25−40 mm thick, permitted to drop out. The total working pattern of filling, separating and purging, and washing down the press can require as long as five hours.

The cylinder or chamber that will push down all the channel chambers is enacted physically or consequently. In convenient channel squeezes, this comprises rather of nuts, which are totally shut until the plates are adjusted or lined up with one another. The choice and utilization of channel material assumes a significant part in the sifting impact. While choosing, fitting channel fabric material and gap will be chosen by the pH worth of channel materials, strong molecule size and different variables to guarantee low separating cost and high sifting productivity. While utilizing, the channel material will be smooth without rebate and gap unblocked. Push plate is associated with the help to put the channel push on the establishment.